Revolutionizing Machining|Next-Generation Turret Turning & Gear Skiving Integration

Featuring a patented direct-drive gear skiving design, delivering exceptional rigidity, stability, and high-efficiency turning.

Now, gear skiving is no longer exclusive to costly, specialized equipment!

By integrating conventional lathe operations with gear skiving processes, we create a true one-stop machining solution —

eliminating process transfers, reducing production time, and significantly enhancing added value.

Empower your production line with higher productivity, optimized workflows, and superior quality.

-

Patented Direct-Drive Gear Skiving Design: Enhanced rigidity and stability

-

One-Stop Machining: Turning + skiving in a single setup

-

No Process Transfers: Save time and handling costs

-

Boost Added Value: Shorter lead times, higher profit margins

-

Wider Accessibility: No longer limited to expensive dedicated equipment

| MODEL | UNIT | FTC-10GS |

| Swing Over Bed | mm | 250 |

| Swing Over Top Slide | mm | 120 |

| Distance Between Center | mm | N/A |

| MAX. Turnable O.D. | mm | 90 |

| MAX.Turnable Length | mm | 120 |

| Angle of the Machine bed | Degree | 15 |

| AC Spindle Motor | AC 7.5KW/10 HP | |

| Max. Spindle Speed | RPM | 100~5000 |

| Spindle nose | ISO | A2-5 |

| Spindle Hole | mm | 52 |

| Through Bar Capacity | mm | 42 |

| Spindle Front Bearing I.D. | mm | 70 |

| Chuck Size | inch | 6"(F-48C) |

| Tailstock Taper | MT | N/A |

| Tailstock Quill Diameter | mm | N/A |

| Tailstock Quill Travel | mm | N/A |

| Tailstock Seat Travel | mm | N/A |

| X-Axis Travel | mm | 250 |

| Z-Axis Travel | mm | 250 |

| X-Axis Rapid Speed | m/min | 15 |

| Z-Axis Rapid Speed | m/min | 15 |

| Min. Input Increment | mm | 0.001 |

| Square Shank Tools Size | mm | 20 |

| Max. Boring Tool Diameter | mm | 20 |

| Numbers of Tool Position | 8 | |

| Change Tool Times | sec | 1.1 |

| Coolant Pump Motor | HP | 1/2 |

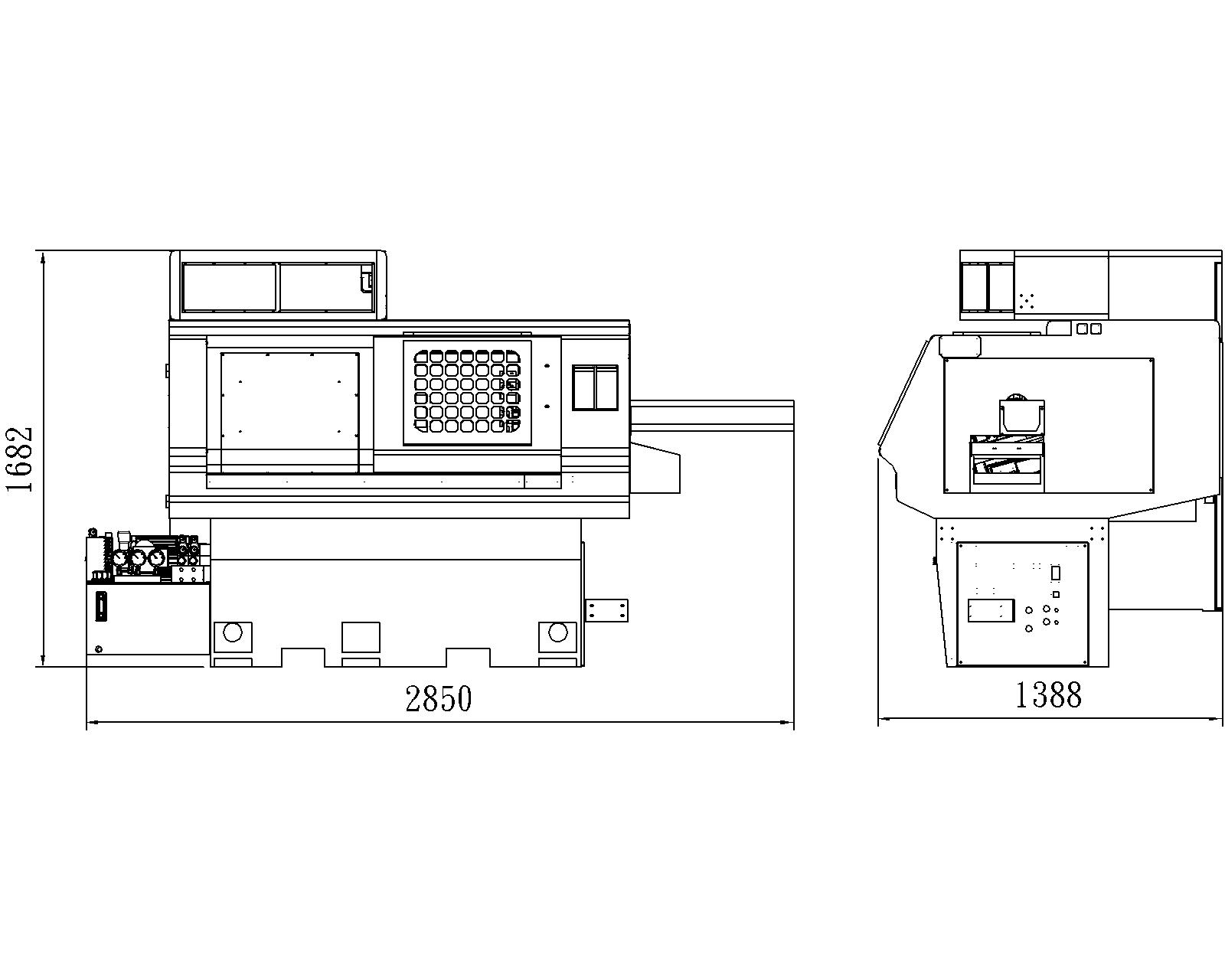

| Machine Dimension | mm³ | 2000*1350*1650 |

| Floor Space | mm² | 2500*3000 |

| Packing Dimension | mm³ | 2640*1600*2250 |

| Machine Net Weight | kg | 2150 |

| Machine Gross Weight | kg | 2400 |

- Parts Catcher

- Workpiece conveyor

- Tool presetter

- Chip Conveyor and moving Cart

- Spindle Air Blow

- Auto power off

- Collet Chuck system (Dia.42mm or Dia. 52mm)

- Transformer

-

- 6" 3-Jaws hydraulic Chuck

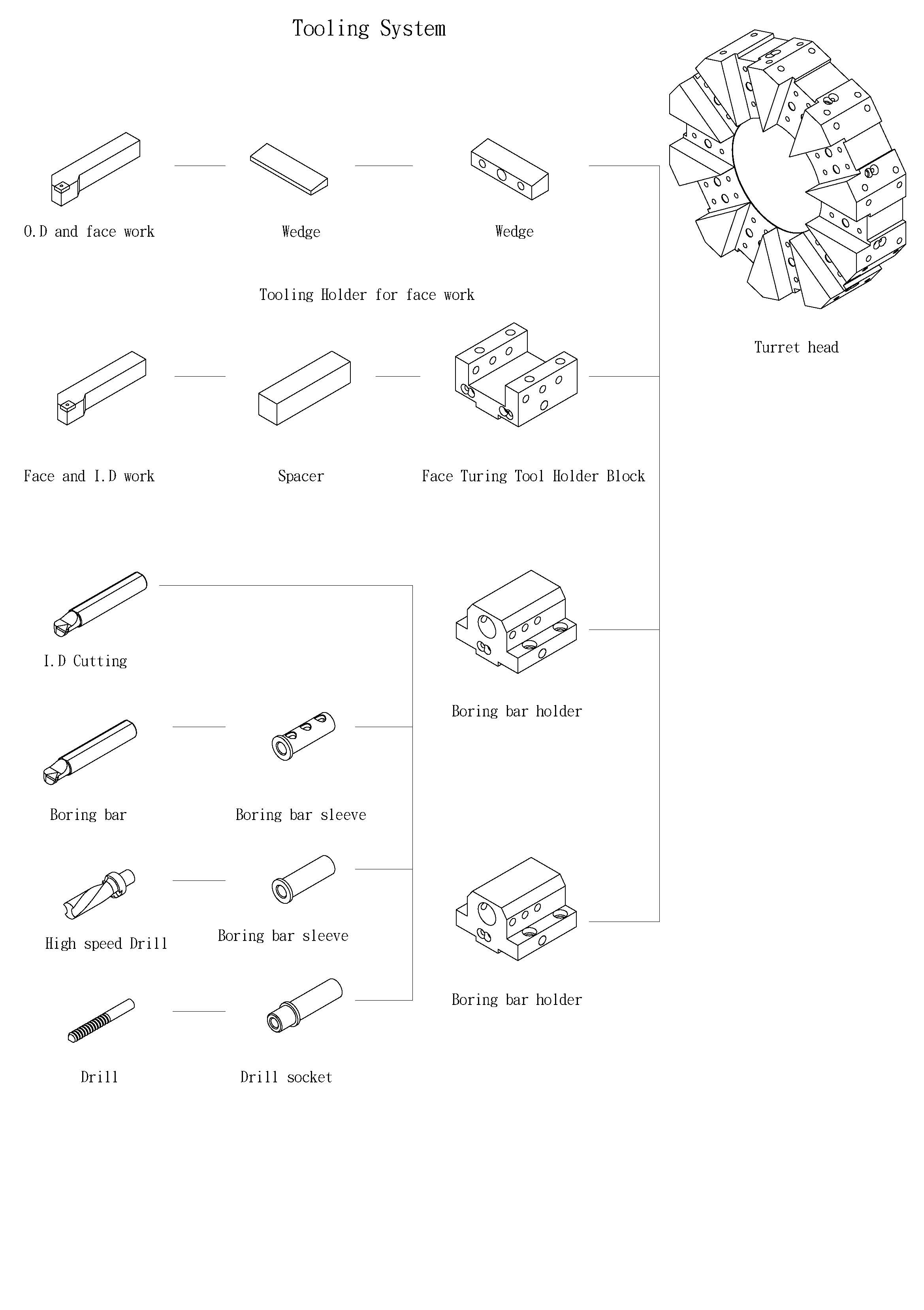

- 8 tools hydraulic servo turret

- Facing Tool Holder 1 pc

- Boring bar tool holder 3 sets

- I.D. Sleeve 8, 10, 12,16mm / each 1 pc

- Soft Jaw 1 set

- Removable coolant Tank

- Coolant system

- Heat Exchanger for electrical cabinet

- Foot Switch

- RS-232 Interface

- Work Lamp

- Levelign bolts and pads

- Tool box with Tool kits

- Machine and electrical operation manual

- Bar feeder interface